The temperature has been steadily dropping into the single digits today. We can at least work inside. Pat has been up in the master framing the loft area over the hallway and installing blocking for the vertical siding to go up on the house at a later date.

Greenbay and I have been working on the floor framing and have been installing the rough sawn exposed rim joists. These you will see from different vantage points on the 2nd floor and will provide a base for the 3rd floor walls to be installed. As you look up at the knee walls from these rooms you will see old rusty corrugated metal we have pulled from the roof of the cabin. I think it will look great. We will have partially vaulted ceilings in all the 2nd floor rooms and then a small storage area located over the shower and laundy on the 2nd floor and accessible from the room above.

It is near zero tonite and Murphy, Pat's dog, appears to want to stay at the house. Pat has gone to Cortez as has his wife, Darcy, and I am not sure if Murphy can get in. Even with the stove going full blast, I begin to worry about Murph, wondering if he will be warm enough. At 11 pm I return to the house. Murphy is curled up by the fire, but the stove is nearly out. I stoke it, plug an electric heater in for him and leave.

The wind has really picked up around midnight and is howling. With a strong north wind our apt. cools off unbelivable quickly and by morning the temp inside is around 50 degrees and it feels very cold. The air temp outside is close to 10 below and with the wind chill was around 25 below zero.

Thursday, November 30, 2006

Nov 28th - Blizzard

It has been snowing all day with blowing snow. We have at least 12" on the ground and it is drifting and blowing everywhere. We haven't had much wind lately but today is exceptional and anywhere the snow can find a way in, it does. When we walk into the house our plastic drapes have let a ton of snow pile up in the house. Greenbay works only a few hours to make some temporary OSB doors. We use bungy cords to make them self closing. Pat has been shoveling snow most of the morning so we can at least traverse around the house and in through the doors. I spend most of the morning cleaning up piles of snow throughout the house and stuffing cracks with insulation scraps from fiberglass batts. Even with the stove going full blast, the house is still very cold but at least warm enough to work in. We staple up plastic wherever we can to fill holes and keep the wintry blast outside.

I am having trouble with my rib cage hurting as well as some tendonitis in my elbows making it tough for me traverse even a simple ladder. The boys recommend I see Holly Bennett who does acupuncture, homepathic remedies and massage. I feel so much better having paid her a visit.

I am having trouble with my rib cage hurting as well as some tendonitis in my elbows making it tough for me traverse even a simple ladder. The boys recommend I see Holly Bennett who does acupuncture, homepathic remedies and massage. I feel so much better having paid her a visit.

Monday, November 27, 2006

Nov 27th - Let It Snow

The sun was shining this morning but there are predictions out for a big snow storm. There are some things I want done before the snow comes. Pat is up on the roof between the chimney and the master installing some trim boards above the metal siding. It's a tough place to get into with a dry roof, but with snow coming we have to complete it. Greenbay helps him cut the necessary trim boards he needs to complete the job.

I have spent the morning down on the north cabin installing the metal skirting around the foundation and bottom logs. It comes out nicely and a large piece of plastic tacked above on the wall helps protect me from the wind which has now picked up. The sky is clouding up. Greenbay leaves before lunch to get to the bank in Telluride as this window will probably be the only one for a few days, especially if you don't have 4wd. Lynn has taken my truck to Cortez to shop for food and pick up the loft windows at the glass company. About the time she arrives back in Rico, the snow begins, light falling at first, but as the afternoon progresses the intensity picks up.

Greenbay and Pat have installed the first of two remaining windows on the north wall of the master. With the final window to install, we find the size is wrong for the opening. Upon inspection it appears to be a tempered glass window for the bathroom. Up on the scaffold, I remove the window that was just installed and Pat and I move into the master. This leaves us one final new window and we must now change the framing and install a new header over the window that is longer. Within an hour or so, Pat has the tear out and new framing completed. He steps out onto the scaffold and we install the last window.

With the oncoming storm, it's now time to button up the rest of the house with plastic over the door openings. One final thing I want to do is insulate the floor of the bay window and install the treated plywood underneath so we aren't laying in a foot of snow. At 5 p.m. Pat is nailing on the plywood underneath.

I am inside sharpening some hand tools for Mary Jane. Pat takes off for Cortez to do some shopping and drop off her tools on the way down. Half an hour later Pat returns and has decided not to go tonite as the roads are bad and traffic is at a crawl down the highway to Dolores. He turns around and comes home...good thing as tonite the wind is howling and the snow coming down like crazy.

No traffic on the highway and only the plows are out. Forecast shows snow for the next two days. I am relaxed tonight with a new sense of ease. Other than some missing doors we are officially dried in and now ....let it snow.

Nov 26th - Roof Completed

I can hardly believe it but today at 5:30 Pat and I completed the roof. We started this morning by completing the fascia on the front of the cabin and then Pat and I installed the necessary flashing. Pat has been on the roof all day and once again I can't say how thankful I am that he loves being on the roof. Soon we are installing the final roof panels on the south side of the roof and we finally come to the final roof panel. Pat installs the ridge cap and the rake flashings and we are done. I have added a few more screws in the flashing on the dining room bay window and we are done for the day. It's good we finished when we did as tomorrow there is a major winter storm coming in..

Sunday, November 26, 2006

Nov 25th - Dried In

Pat and I have spent today completing the drying in of the cabin roof. Once the thin layer of plywood has been applied to old roof spaced sheeting, he has applied the felt paper over this and completed the vapor barrier. Next the 2 x 10 rim joists are applied on the south side of the roof and these will create the border for the insulated panels. I spend most of the day cutting the insulated panels and de-icing the necessary edges of the panels that go up against the 2 x10's.

We are now on the final sheets of the insulated panels and my figures on how many panels were needed were really close. Near the top of the roof I have had to use remaining scraps to complete the installation and considering we had over 2,000 sq ft of roof area, we have only small scraps left after the job is complete. Pat buttons the roof up with another layer of bithuthane and felt. We have 3 fascia boards to install and the installation of the metal to finish. Tomorrow we hope to have the entire structure completed with steel with only the porchs remaining to frame and roof.

I have a muscle around the left side of my ribs that has been giving me fits and is slow in healing making it difficult for me to make certain motions. I am hoping it will get better soon. Since tomorrow is Sunday, we hope to have some quiet work inside once the roof is on and hopefully I can get further along on running the water lines. Our timing looks good on the roof as a major snow storm is expected this week...More pictures coming soon.

Saturday, November 25, 2006

Nov 24th - Cabin Gets A Roof

Pat and Bill have come today and we have started on the cabin roof again. We first complete the insulated panels on the north side of the roof. We have also added the main fascia board on the north side of the cabin. Pat has cut the steel for the north side of the roof. Bill and I begin the fascia for the south side and then apply the plywood on top of the space sheeting. I have to notch the oak beam and post on the southwest corner of the new section of house. This has to be completed before the side wall flashing can be installed. I've managed to split my finger open in the process and several hours later, Bill slices his finger on some staples inside his tool pouch.

Later in the afternoon it begins to look like snow up on the mountain, but none is in the forecast. A bit later the snow starts to come down and Pat is still on the roof. Hurriedly we get the remaining felt tacked up on the south side of the roof. With only 3 more pieces of plywood to go we will be done, but the snow is coming and it has to get covered. Bill and I drag the reinforced plastic up on the roof for Pat who pulls it over the north side of the roof. We have learned that the snow doesn't slide so well off the roof when there is paper and cleats. Hopefully it will be clear tomorrow and then by pulling the plastic off, the entire roof is clear of snow and ice.

Once Pat and Bill leave, I head back upstairs to install the remaining water lines in the master. While the PEX is easy to install, the much harder task is drilling through some of the floor joists.

The TJI's are much easier because they have knock-outs installed about every 16". Simply hitting them with a hammer, they pop out nicely and make a perfect hole for installing a couple of water lines.

The PEX tubing is nice because it requires no tape measure... just run the pipe along the route you need, hook up the 4 piece fitting to the Manabloc manifold, which is a simple procedure, and then install the necessary plug or angle fitting where the pipe is to be attached to the fixture. By evening, I have completed all the water lines to the master.

Later in the afternoon it begins to look like snow up on the mountain, but none is in the forecast. A bit later the snow starts to come down and Pat is still on the roof. Hurriedly we get the remaining felt tacked up on the south side of the roof. With only 3 more pieces of plywood to go we will be done, but the snow is coming and it has to get covered. Bill and I drag the reinforced plastic up on the roof for Pat who pulls it over the north side of the roof. We have learned that the snow doesn't slide so well off the roof when there is paper and cleats. Hopefully it will be clear tomorrow and then by pulling the plastic off, the entire roof is clear of snow and ice.

Once Pat and Bill leave, I head back upstairs to install the remaining water lines in the master. While the PEX is easy to install, the much harder task is drilling through some of the floor joists.

The TJI's are much easier because they have knock-outs installed about every 16". Simply hitting them with a hammer, they pop out nicely and make a perfect hole for installing a couple of water lines.

The PEX tubing is nice because it requires no tape measure... just run the pipe along the route you need, hook up the 4 piece fitting to the Manabloc manifold, which is a simple procedure, and then install the necessary plug or angle fitting where the pipe is to be attached to the fixture. By evening, I have completed all the water lines to the master.

Nov 23rd - Thanks-giving...er I mean roofing..

It's Thanksgiving day and we will have dinner at the Rico Hotel. Lynda and Aemon run the restaurant which opens tonite for the weekends. We always look forward to one of his famous 5 star chef meals... but in the meantime work goes on at the house. Only Greenbay has come up today and we get in a few hours of work before a neighbor asks us to be quiet around noon. With an open roof it is difficult to stop, but we do and cover the roof up with plastic. A big storm is brewing for next week and I have to get the roof on the cabin completed.

Lynn has done a thorough house cleaning and sweep up of the entire house which was desparately needed. At least you can walk around in the house without tripping on scrap wood. She has even cut up remaining scrap and stacked it on the wood pile in the house. The wood pile outside continues to grow and there is at least a couple of cords of scrap wood on the ground.

After lunch we start running more PEX water lines up into the master. I figure if I can work on it a little every day, especially after everyone has gone home, I should have it completed in a few weeks. Today, I complete the water lines to the master vanity and and toilet.

Lynn has done a thorough house cleaning and sweep up of the entire house which was desparately needed. At least you can walk around in the house without tripping on scrap wood. She has even cut up remaining scrap and stacked it on the wood pile in the house. The wood pile outside continues to grow and there is at least a couple of cords of scrap wood on the ground.

After lunch we start running more PEX water lines up into the master. I figure if I can work on it a little every day, especially after everyone has gone home, I should have it completed in a few weeks. Today, I complete the water lines to the master vanity and and toilet.

Thursday, November 23, 2006

Nov 22nd - Roof On

Pat has completed the entire roof over the master bedroom with all the steel needed. It is indeed a relief that the weather has held and is still holding with warm and sunny weather continuing.

I have gone up on the road by the mill to get a small 4' piece of lodge pole pine to use to patch two of the rafter upper ends that had been cut out for a brick chimney years ago on the old cabin. Up on the road above the mill, which isn't maintained this time of year, I drive past the old landmark Douglas Fir Tree; probably the only surviving old growth timber in the area. This one was saved because it was used as a survey marker. At the base it is around 5' in diameter and who knows how old. A little farther up, I find a fallen dead pine and I cut the small section out of the tree and head back into Rico.

Something is making a noise under my truck and I stop on the main road only to find my right rear tire has been cut by a protruding rock and completly ruined. I've never had a flat on the truck before and proceed to change it out with my spare. Luckily I have a spare with me and I find that the wheel wrench is the wrong size. I happen to have my tool box with me and a spare socket that fits. It turns out this little hunk of dead timber not only cost me some time but a new tire as well. When I return to the house, I find it's a common incident losing tires up on the mill road...and part of living up here.

Greenbay and Bill continue on the old cabin, installing fascia on the north side as well as some old thin weather plywood I have to go over the space sheeting on the roof. Portions of the plywood need to look old as the sheeting on the inside will be exposed. Near the end of the day, Pat joins them and they have a portion of the 2 x 10 rim joists and roof panels installed on the north roof.

Tuesday, November 21, 2006

Nov 21st - Roof Off

I have helped Pat move steel up on the roof. He will be close to finishing the roof today. How he can continue to stay on the roof all day is still hard to understand, but he seems to love it. By tonite the roof is completed except for the ridge cap.

Bill and Greenbay have completed tearing off all the old tin and cedar shingles from the old cabin. We have had to remove one piece of the skip sheeting on the roof because of some old holes cut for a stove pipe. Thousands of square headed nails have to be removed from the sheeting. This indicates that the shingles are probably original and still intact after 125 years which is amazing. I've kept the old tin and stacked it along the fence and hope to use it somewhere in the house at a later date.

I have continued on with preparing the north wall of the north cabin for tin along the bottom. This will keep the weather out. I have installed the two foundation vents as well as the insulation. I'll be ready for the steel tomorrow.

After hours, I tackle a broken PVC pipe fitting in the crawl space that I managed to break while installing water lines. It takes me nearly an hour to get the fitting out without breaking the larger fitting it was originally glued into. I also add a vent for the floor drain in the mechanical room. I return home late.......Lynn's return is evident as I open the door to delicious smells of a hot cooked meal.

Nov 20th - Errand Boy

I have had numerous errands to run in Cortez, Dolores and finally Durango where I've gone to pick up Lynn at the airport. We have returned home late.

Meanwhile, Greenbay and Pat have completed the fascia on the master and installed the neccessary flashings. Everything is ready for steel now.

Meanwhile, Greenbay and Pat have completed the fascia on the master and installed the neccessary flashings. Everything is ready for steel now.

Nov 19th - Man-a-bloc

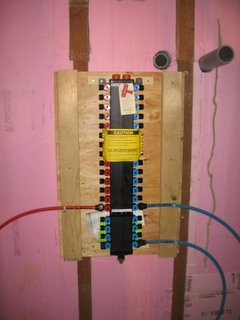

I've begun the installation of the water lines today. I have had to complete the foam insulation on the walls where the Manabloc will be mounted. This device distributes water to each appliance with the same pressure. Without the use of branch lines and in-line tees, the Manabloc is a great improvement over copper water lines. Not only does the pressure remain constant, but installation takes a fraction of the time. I've installed a piece of 3/4" plywood on the wall, attached the Manabloc and then drilled holes through the floor joists and run supplies to the 1st floor 1/2 bath.

Saturday, November 18, 2006

Nov 18th - More Roof Panels

Bill has completed the bituthane around the south master windows and Greenbay helps him get the aluminum scaffold moved to the north side. Pat, once again spends the day on the roof, while Greenbay and Bill prepare the roof panels to go up on the roof. By the end of the day, Pat has completed the installation of the roof panels on the north side of the roof.

I have been completing the rough cut rim joists over the 2nd floor bedrooms. I've also capped the top of the interior walls with 2 x 6's so we will have nailers for the drywall on the ceilings. I have been working on preparing the entire floor system for the 3rd floor. It's my hope that how I frame it will make a difference in how quickly the flooring and drywall will go in.

Nov 17th - Skylights

The skylights have arrived today and Pat and Greenbay hoist them onto the roof. Pat continues to apply steel and build all the flashings around the skylight. It's a tedious process that requires attention to detail to make sure that the skylights on the metal roof don't leak.

Bill has been completing the framing for the floor system and installing the TJIs upstairs over the 2nd floor. The framing is coming together nicely. Bill and I have moved several piles of lumber to get access to the pink foam I will need to finish insulating the concrete wall and the outer logs around the foundation. We have restacked much of the lumber both out front and out back so we will have better access.

I have been up in the master preparing the flashing and framing for the windows. Greenbay and I spend the afternoon getting the the 3 south windows installed.

Thursday, November 16, 2006

Nov 16th - More Steel

It's warmed up to 50 degrees today and time to tackle more roofing. I've moved 6 24' sheets to the edge of my trailer and started the gas powered cut off saw to cut through the stack. They need to be cut twice as the sheets are a bit too long. Pat and R.D. are once again on the roof completing the fascia on the south edge of the roof. They have managed to complete about 1/2 of the south side with steel including installing a roof jack for the main plumbing vent. The steel is not only heavy in weight, but in gauge, making it difficult and time consuming to cut. I have an old circular saw that was on its last leg and we've used it for cutting steel with a carbide metal blade. It's finally bit the big one. I toss it into the dumpster and hence the cut off saw. The stacks of metal also have to be drilled and my cordless Dewalt drill bites it too. Must be something in the stars.

Greenbay and Bill are inside and have nearly completed the framing and layout for the floor system on the 3rd floor. Tomorrow we should be ready for warm board inside. Hopefully we will get some insulated panels up tomorrow as well.

This afternoon, I've decided to work on beginning the installation of the same steel panels that will protect the lower part of the house around the foundation. Here in snow country, the snow sliding off the roof can pile high on the north side of the house. I remember spending my first night in the cabin back in 1994 on Memorial Day. There was still snow drifted to the roof at the end of May. The existing cabin has no windows on the north side, but both of the old cabins we have reconstructed have one north window. If I don't get the metal in now along the base of the cabins, it will be spring before I can attempt it. The 2 north windows will require shutters that will help keep the snow out and protect the windows from snow sliding off the roof.

Greenbay and Bill are inside and have nearly completed the framing and layout for the floor system on the 3rd floor. Tomorrow we should be ready for warm board inside. Hopefully we will get some insulated panels up tomorrow as well.

This afternoon, I've decided to work on beginning the installation of the same steel panels that will protect the lower part of the house around the foundation. Here in snow country, the snow sliding off the roof can pile high on the north side of the house. I remember spending my first night in the cabin back in 1994 on Memorial Day. There was still snow drifted to the roof at the end of May. The existing cabin has no windows on the north side, but both of the old cabins we have reconstructed have one north window. If I don't get the metal in now along the base of the cabins, it will be spring before I can attempt it. The 2 north windows will require shutters that will help keep the snow out and protect the windows from snow sliding off the roof.

Wednesday, November 15, 2006

Nov 15th - Digging Out

I have had a ton of paperwork to take care of this morning and afternoon and it seems like I haven't done much today. I have been working on proofing the new Vintage Power Wagon's catalog last night until midnight and didn't get my quota for sleep which doesn't help.

R. D. has come back for a few more days of work before he leaves for the holiday. I had him stop at Timberline Hardware in Telluride and pick up a snow rake for me. I hadn't seen these before but they are great. Using extendable aluminum handles that lock together up to 30', the flat aluminum pan on the end with small rubber wheels pulls snow off the roof. We have to get the snow off the north side of the master so the ice can disappear when it warms up. We still have one whole side of the roof to complete the insulated panels on.

Pat has completed the final framing of short knee walls above the bath and master closet upstairs while R.D. has been pulling and pushing snow from the roof. Once he is finished, I go out front and start pulling snow from our metal roofing pile as well as any other materials we will need to complete the roof and floor framing for the 3rd floor under the main roof. It's hard work and I have forgotten just how much fun shoveling snow is.

Later in the afternoon I have completed all the vent lines up to the peak of the roof. Once the roof is ready I have to extend a 3" vent line through the roof and attach the pipe flashing. This is the highest point of the roof.

Pat and R.D. are out on the scaffold on the south side of the house attaching the fascia boards that I picked up in Dolores. We have installed a propane heater inside the master and hopefully after the heat is on, the snow on the north side of the roof will melt.

Greenbay and Bill are on the inside and Greenbay has laid out and installed the rim joists for the 3rd floor. Bill has spent a good part of the day filling in framing between the top log of the garage and the warm board above. This will help make solid the entire structure. The top of the log is far from straight and very curved and so it takes some time to complete it.

Warm weather due tomorrow and we certainly need it. I need to get the roof finished. Was going to take more photos tonight and camera batteries are dead. I will replace them and take more tomorrow.

R. D. has come back for a few more days of work before he leaves for the holiday. I had him stop at Timberline Hardware in Telluride and pick up a snow rake for me. I hadn't seen these before but they are great. Using extendable aluminum handles that lock together up to 30', the flat aluminum pan on the end with small rubber wheels pulls snow off the roof. We have to get the snow off the north side of the master so the ice can disappear when it warms up. We still have one whole side of the roof to complete the insulated panels on.

Pat has completed the final framing of short knee walls above the bath and master closet upstairs while R.D. has been pulling and pushing snow from the roof. Once he is finished, I go out front and start pulling snow from our metal roofing pile as well as any other materials we will need to complete the roof and floor framing for the 3rd floor under the main roof. It's hard work and I have forgotten just how much fun shoveling snow is.

Later in the afternoon I have completed all the vent lines up to the peak of the roof. Once the roof is ready I have to extend a 3" vent line through the roof and attach the pipe flashing. This is the highest point of the roof.

Pat and R.D. are out on the scaffold on the south side of the house attaching the fascia boards that I picked up in Dolores. We have installed a propane heater inside the master and hopefully after the heat is on, the snow on the north side of the roof will melt.

Greenbay and Bill are on the inside and Greenbay has laid out and installed the rim joists for the 3rd floor. Bill has spent a good part of the day filling in framing between the top log of the garage and the warm board above. This will help make solid the entire structure. The top of the log is far from straight and very curved and so it takes some time to complete it.

Warm weather due tomorrow and we certainly need it. I need to get the roof finished. Was going to take more photos tonight and camera batteries are dead. I will replace them and take more tomorrow.

Nov 14th - Let it Snow...

The snow has been coming down most of the day and by evening we have nearly a foot of snow on the ground with blowing and drifting snow around the house nearly 2' deep in places. Luckily we have the wood stove fired up and the first floor is very warm, but above on the 2nd and 3rd levels, it's still breezy and cold with so many air leaks unplugged.

Bill has been installing blocking all day on the 2nd floor walls using up our scrap 2 x4's. The blocking will provide a solid nailing surface for the vertical siding to be installed on the outside of this portion of the house.

Pat has completed attaching the treated lumber to the concrete wall near the stairway and has started filling in between the studs he has shot to the wall with the foam insulation scraps we have around. We need more, but right now they are buried in the snow.

I have been up on the 3rd level framing interior walls for the master suite and when Pat finishes down below he comes up to give me a hand. We have pre-drilled many of the studs for horizontal vent lines which are normally much harder to feed pipe through as well as drill holes for. Some extra planning at this stage makes the job go easier. I complete the gluing of the PVC pipe and fittings in the master bath, but not before I manage to kick over the can of purple pipe primer on the floor. Some rags and it's wiped up quickly, but the fumes linger. Framing these upper walls has strengthened the entire structure and I add a solid 4 x4 post above the north/south oak beam that will support the main east/west ridge beam.

Bill has been installing blocking all day on the 2nd floor walls using up our scrap 2 x4's. The blocking will provide a solid nailing surface for the vertical siding to be installed on the outside of this portion of the house.

Pat has completed attaching the treated lumber to the concrete wall near the stairway and has started filling in between the studs he has shot to the wall with the foam insulation scraps we have around. We need more, but right now they are buried in the snow.

I have been up on the 3rd level framing interior walls for the master suite and when Pat finishes down below he comes up to give me a hand. We have pre-drilled many of the studs for horizontal vent lines which are normally much harder to feed pipe through as well as drill holes for. Some extra planning at this stage makes the job go easier. I complete the gluing of the PVC pipe and fittings in the master bath, but not before I manage to kick over the can of purple pipe primer on the floor. Some rags and it's wiped up quickly, but the fumes linger. Framing these upper walls has strengthened the entire structure and I add a solid 4 x4 post above the north/south oak beam that will support the main east/west ridge beam.

Tuesday, November 14, 2006

Nov 13th - Inside Framing

It is snowing again this morning and there isn't any way we can work outside. Greenbay and I have shifted the work to laying out the master walls for the bath and closet. We make some headway and then after lunch Greenbay is MIA...I guess we will find out where he was tomorrow. I have finished setting up one of the walls where plumbing will be installed inside the wall. Knowing where the pipes run helps me plan where to drill holes in the wall for the vent lines.

Pat is downstairs in the mechanical room and bath completing the framing so we can install electrical wire and complete the water lines which I hope to start on next week. Pat is really a jack of all trades and seems to handle anything I give him. I have enjoyed working with him.

Bruce drops by and does a major clean up of the house and cleans our tool room which has desperately needed some attention.

The garage door guy has shown today which surprised me because of the weather. He completes the installation of the garage door with the applied metal I have supplied. Within months the metal should begin to rust just like the roof.

Pat is downstairs in the mechanical room and bath completing the framing so we can install electrical wire and complete the water lines which I hope to start on next week. Pat is really a jack of all trades and seems to handle anything I give him. I have enjoyed working with him.

Bruce drops by and does a major clean up of the house and cleans our tool room which has desperately needed some attention.

The garage door guy has shown today which surprised me because of the weather. He completes the installation of the garage door with the applied metal I have supplied. Within months the metal should begin to rust just like the roof.

Sunday, November 12, 2006

Nov 12th - Snow Bound

It started snowing during the night and then snowed off and on this morning. By noon the sun is out and the snow is starting to melt. We received about 6". This is the most snow little Max has ever seen, being a Florida dog. He's like a little snow plow pushing his way through the snow drifts. Being a little dirty, his white hair stands out against the snow.

I've spent the day at the house, with the wood stove burning while working on completing the drain lines. Most of the work I have to do is laying out and installing the drains up to the master suite located above the garage. This week we will get the interior framing installed in the master and I can continue with the plumbing up through the roof.

Saturday, November 11, 2006

Nov 11th - Fire It Up

This morning is cold and when I show up at the house, I decide to fire the wood stove up. Within minutes the smoke is pouring out of the new chimney and the old Cub pot belly stove is putting out the heat with only a small amount of wood. By now all the wood scraps have created a large pile of at least a full cord of wood. I also have a huge stack inside the living area waiting to keep the place warm.

Bill and I have given the place a good house cleaning and make sure that the tarps are covering all the different piles of lumber. Snow and/or rain coming in tonight. Bill completes the Tyvek for the entire house this morning and then heads off for the Grand Canyon.

Pat is up on the roof once again. Today he completes the entire main section of the roof and finishes any last minute covering of the master suite with felt paper. We prepare for the oncoming storm. I've gone up to the master suite and covered the window openings the best I can to prevent as much of the storm as possible from entering the building. Later in the afternoon I complete the plumbing on the 2nd floor and begin the plumbing the drain lines from the garage up to the master suite. Hopefully a few more days and I will have the drain lines completed.

Friday, November 10, 2006

Nov 10th - Green Bay Bridge

It's time to bring up the insulated panels onto the roof which has proved challenging. Before, when we were installing the panels, we simply moved them up onto the master suite floor and then hoisted them up onto the roof. Now, with the walls on the master suite up and the roof enclosed, we have to figure out a way to get the panel up over the overhang and onto the roof. While not too heavy, they are bulky. Greenbay has devised a simple bridge or crane using some 2 x 4's nailed onto the peak of the roof. We have borrowed Mike Hagen's large pulley and rope he uses for hoisting buckets of mortar to high elevations. We drill a hole in each panel attach the rebar hook through the panel and then pull the rope and watch the panel find its way to the top of the roof. We call his device the Green Bay Bridge.

Today is payday and usually several of my help leave early to take care of banking needs since there is no bank or ATM in Rico. Still they have managed to attach panels and complete the south side of the roof. Pat, as usual, is on the roof helping R.D. screw the panels into the rafters below.

Bill and I have to ready the garage door opening for the installation of the garage door on Monday. We have had to attach flat rough cut 2 x 6's to the inside of the jamb which will accept the garage door track. A simple job in most cases, but here, dealing with inconsistent thicknesses of logs makes the job tougher and we have to notch the logs all the way down the edge of the trim board so they fit tight against the jamb. Bill has also been completing the final sections of Tyvek in areas on the house. Hopefully by tomorrow we will have that job completed as well as a few small sections of steel on the roof finished.

Thursday, November 09, 2006

Nov 9th - Getting Closer

R. D. and Greenbay have completed the dry in on the roof over the master. Greenbay continues cutting two holes in the roof as I have decided to add to fixed skylights to allow more light in the room.

R.D. and I have added some bracing for the aluminum scaffold on the south side of the master. R.D. is on the roof again, along with Greenbay, and near the end of the day they have nearly completed the rim joist.

I have the great job of using the SIPS hot knife for cutting the edge of the stryofoam panels. The fumes are bad enough that no one wants to be around when the cuts are being made and so with my mask on, I make the cuts on 6 panels to begin the process of getting the roof dried in. Weather is coming soon and we need to get the panels up as quickly as possible tomorrow.

Pat continues on the roof and has it nearly buttoned up. The flashing has been particularly time consuming but he has done a superb job flashing against the master suite wall and fireplace. With another couple of hours we will be complete on the roof. We've picked up Pat's metal brake and used my new power shear for cutting metal and bending it into the flashings we need.

Gary from Adams Overhead Door has stopped by to pick up the steel to face the garage door which will be installed next week. Bob Aikey has also stopped by to give me some direction for installing boxes and wire for the electrical system. Being a master electrician, he will be sure I get the work done properly for our inspection.

Tonight I have stayed late and Greenbay drops by and helps set up our new work lights. By the time I quit for the day I have the entire 1st floor completely plumbed with drain lines up into the 2nd floor. The drain for the washer is now installed as well as the drain for the shower.

R.D. and I have added some bracing for the aluminum scaffold on the south side of the master. R.D. is on the roof again, along with Greenbay, and near the end of the day they have nearly completed the rim joist.

I have the great job of using the SIPS hot knife for cutting the edge of the stryofoam panels. The fumes are bad enough that no one wants to be around when the cuts are being made and so with my mask on, I make the cuts on 6 panels to begin the process of getting the roof dried in. Weather is coming soon and we need to get the panels up as quickly as possible tomorrow.

Pat continues on the roof and has it nearly buttoned up. The flashing has been particularly time consuming but he has done a superb job flashing against the master suite wall and fireplace. With another couple of hours we will be complete on the roof. We've picked up Pat's metal brake and used my new power shear for cutting metal and bending it into the flashings we need.

Gary from Adams Overhead Door has stopped by to pick up the steel to face the garage door which will be installed next week. Bob Aikey has also stopped by to give me some direction for installing boxes and wire for the electrical system. Being a master electrician, he will be sure I get the work done properly for our inspection.

Tonight I have stayed late and Greenbay drops by and helps set up our new work lights. By the time I quit for the day I have the entire 1st floor completely plumbed with drain lines up into the 2nd floor. The drain for the washer is now installed as well as the drain for the shower.

Wednesday, November 08, 2006

Nov 8th - Master Suite Ceiling

R. D. and Greenbay have begun the task of nailing down the ceiling liner or decking that will be exposed in the master suite above the oak rafters. These are the heart pine slabs we had been working on straight lining. While Greenbay cuts, R.D. nails the panels on and when enough courses are completed, he rolls out 30 lb. felt paper on the top.

By evening, the south side of the roof is complete and dried in and about 2/3 of the north side is completed. Tomorrow we will actually have this portion dried in. The ceiling liner looks great as you can see from the photo.

Pat is up on the roof all day completing the chimney flashing and attaching more roof metal. He has also started cutting and installing some aged galvanized siding material that were old panels from the addition we tore off months ago. Since the main roof is not much lower than the master roof, we think it best to side the exposed portion of the west wall of the master with metal instead of wood siding. If the snow sits on the roof, short pieces of wood siding could easily be buried in snow.

Bill and I spend the morning installing the 2 hand hewn oak posts at the rear of the garage. These posts support the cantilevered large beam which ultimately supports the entire east wall of the master bedroom. After lunch we install the 3 garage windows which now aren't in danger of being water damaged since the roof is nearly dried in.

The weather continues to hold and what a beautiful warm sunny day today. With another 10 days of this we could be completely dried in with metal on the roofs and windows and doors installed.

Tuesday, November 07, 2006

Nov 7th - Before and After

Nov 7th - Up On The House Top...

Hagen has completed the stonework on the chimney and it looks fabulous. I am thoroughly pleased with the way it looks and Pat has done a fine job of installing the flashing under the stone. R. D. has spent a good part of the day helping Pat tear off Hagen's work platform from the north side of the roof. Pat had sturdily built it himself to hold a stone mason and a lot of rock. Now it's time for it to come off. R. D. and Pat continue on the roof and by the end of the day the north side of the roof is close to being completed. Pat will complete the main section of the roof and hopefully the weather will hold for at least another day. We have been so fortunate with the weather these days and it makes such a difference in progress.

Bruce has arrived this afternoon and I have him clean out the attic of the cabin of all the used lumber that has been sitting up there since summer. Most of it is short and I have had him stack all the short lumber inside the crate where the leaded glass windows had been sitting. It makes a perfect area to store the short boards that we will be needing later on.

Greenbay and I have completed all the roof framing for the master suite and it's now ready for decking which is also ripped down now to a consistent width. It should go fairly quickly tomorrow and weather permitting, we should actually be dried in by tomorrow night and ready for the rim joists for the insulated panels. Hopefully, within a week we will have the steel roof on over the master suite. It has been an exceptionally difficult roof to frame even with a simple layout as the rafters are solid oak and each fastener must be pre-drilled because the oak is so hard. The old oak rafters look great and are of great quality dried white oak.

Bill has helped R. D. and me install the final leaded glass window in the main part of the house and the first and 2nd floor are now complete with all the windows. Only the master suite and garage remain and these will be ready as soon as the roof is on.

Pat has helped me tonite install the old wood pot belly stove on the first floor and we have it hooked up and ready to go as soon as the weather turns cold. It's exceptionally warm tonight and while I have a coat on, my hands are not cold. I spend 3 more hours this evening preparing more drain lines and fittings for the 2nd floor bath and laundry. With a little cutting tomorrow, the plumbing drain lines will be complete over the kitchen area. I am beat...

Monday, November 06, 2006

Nov 6th - Leaded Glass Windows

R. D. has opened up the crate that has been sitting for months and removed the first leaded glass windows from the crates. I remember months ago my neighbor Mark and I building the crates and then crating the windows in Iowa for the long journey to Colorado. At last they are ready to install and I am anxious to see how they look. First up is the octagon shaped window going in the 2nd floor bath. R. D. has to add the diagonal openings to the rough window opening before he can install the window into the opening. Soon it's up and it is amazing how much light the window refracts through the honey comb glass.

Bill and R.D. go to install the west loft windows which are made from old door transoms. One is emerald green glass and the opposite is ruby red glass. Originally they were installed horizontally above some exterior entrance doors from an old house in Richland, Iowa. Interesting how they originated in Richland and ended up in Rico (which means rich in Spanish).

Unfortunately, R. D. discovers a large crack in the emerald glass that grows larger once it's installed. The old wooden frames are actually made from walnut wood and I have kept the original paint on the outer frames. Once I see the crack and the two windows next to each other, I decide that the colored glass needs to be removed and clear, old style glass needs to be reinstalled. These two high windows I had designed to bring in some color high up in the loft on the 2nd floor. Now that I have added a 3rd level in the upper portion of the house, this new room requires more light anyway. I will plan on changing the glass at a later date.

Next we install the south kitchen leaded glass window. It's the first big window we install and weighs around 300 pounds. It takes 4 of us to get the window inside and into place. Next, R.D. has built a scaffold over the stairwell and this one is a little tougher as we have to lift it high on to a rolling scaffold and then slip it through a stud bay on the 3rd floor level. They all mount nicely and look superb. I couldn't be happier.

Towards the end of the day, we install the west facing leaded glass window into the north bedroom. Out on the pump jack I install the mounting screws while Greenbay, R.D. and Greenbay steady and level the window from the inside. One more to go in the west bedroom tomorrow.

Bill and I have spent a good part of the day completing all the straight lining and ripping of the heart pine decking which will go up later this week over the rafters in the master suite. Greenbay has been working on the oak blocking that he installs between rafters. It's especially tough as it's not nailable and so he ends up drilling and screwing the blocking in. Another job that requires all of our help is getting the 5 x 9"-16' long oak beam from ground level up 16' so that each end rests on the south and north walls of the master suite. It takes 5 of us to get the beam into the place.

Pat and Gary are still on the roof and have completed the steel installation on the south slope. They have moved down to the first floor and completed the steel roofing on the bay window in the dining room. Hagen is still on the roof and in the late afternoon completes the stone work on the north slope. It's covered up again and the heat turned on. Hopefully tomorrow we will get to remove his work platform and begin work on the north slope of the roof.

Nov 5th - Cut Away

Another Sunday of Cutting. Pat is with me today and we start by unloading all the nice 1 x 12's I picked up in Dolores. While Pat prepares for more steel on the roof, I begin straight line cutting all of the heart pine decking. By noon I have quite a pile which now has one side of each board nice and straight. I've chosen a nice long 16' straight 2 x 4 as a straight edge. Using some grabber screws I attach the straight edge to each individual board and then run my worm drive Skil saw down the edge.

Pat requires my help this afternoon and I go down to the trailer where we have the steel stacked. He shows me what he wants drilled as the holes for the washered screws have to be drilled. Greenbay has fabricated a ladder made from 2 x 4's that Pat tacks to the roof to climb down to the edge of the roof. He has helped me haul the 20' long sheets of steel up to the south side of the house and we stand them up so the upper edge is just above the edge of the roof. Pat has fashioned a handle from a bucket handle and by drilling two small holes near the top edge of each sheet of steel, he is able to drag the steel onto the roof while I stand below lifting and pushing. It still amazes me how comfortable he is on the roof.

Bruce has stopped by to do more cleanup and I've set him up with a chop saw to complete the cutting of firewood scrap that has once again been piling up. Not only has Bruce never used a chop saw... he doesn't even know what a chop saw is. Within minutes he has a rhythm rolling on the saw with his ear and eye protection gear in place. He is enjoying himself and I like that someone besides me is cutting up the scrap soI can focus on other things.

Hagen is back and has the block of the chimney well above the peak of the roof. Today he begins laying stone on the outside of the chimney. Pat has prepared a ledge for him to lay the stone on and before long he has a large section of the stone laid above the roof. It's dark now and Mike, myself and Pat are scrambling to hook up a propane heater up on the roof. Finally the right hoses, fittings and tanks come together and by 6:30 we are finished. I can hear the propane heater running on the roof which will prevent the mortar from freezing. None of this is new to Pat and Mike who have spent many a winter evening protecting masonry work from freezing.

Sunday, November 05, 2006

Nov 4th - A Very Full Day

I've left for Cortez and Dolores at 7:30 am this morning. I've stopped off at Mary Jane Millard's place at Stoner. I drop off my photos for her to enjoy looking at today while I am doing my shopping. I will also pick up some groceries for her and drop them off on my return trip.

I've stopped at Val Truelsen's place in Dolores. He was referred to me by Corky McClain, the plumber who had come to Rico last week to look at doing my heating system. Corky was a good friend of my grandparents, Chuck and Lenore Lee. Corky reminds me of an incident that happened 30 years involving my grandmother. For years they had lived next door to old ramshackle run down house that had been a rental with some fairly seedy tenants. The house had come up for sale and my grandparents had bought it hoping to keep more bad tenants out of the house. My grandmother needed a new garbage disposal one day and offered Corky a deal of a lifetime. She actually traded the entire old house for a garbage disposal for their own house. Corky, thinking it would be an easy house to move, did just that by doing some horse trading with a house mover and a foundation man. He installed heating systems for them and these guys moved the house (which had been originally constructed out of Rio Grande Southern railroad ties). The house still stands today near the school in Dolores.

Back to Val's place...knowing many of my related family members, he has given me permission to go into his yard while no one is there. I've come to search for the long rough cut 1 x12's I need to complete some of the siding on the front of the house and also the fascia on the master suite as well as the fascia on the cabin.

Lumber is scattered over several acres and I find only small amounts of the lumber I need in many different areas. When I'm finished I've managed to find 400' of 1 x 12's which will help me complete the job. I've stopped off in town to let him know how much I picked up and will stop later on my way back to pay him. He gives me a reasonable price and with a full load of lumber poking out of the back of my truck, I head for Cortez.

First stop is the drive up window at the bank for some quick cash and a pee break for Max.

Next, I stop at Belt Salvage to see if I can find some rusty steel grate for my steps, but nothing in the scrap pile. Still I find a great piece of 1/4" sheet steel that's come out of laser cutting shop. It has perfectly cut little boomerang shaped pieces cut out of a blank. I love the shape and it will make a nice table or grate for something in the house. I also find a large rock screen for sifting different sizes of gravel. I love the way this stuff looks; it's like a large scale woven cloth with wire 1/2" thick. Needless to say, I don't leave empty handed.

Next door to Belt is Standard Plumbing and I've stopped in to pick up some PEX fittings for my water system. It's about closing time and I decide to call my cousin Grace to see if she and Pete would like to have lunch. Pete is not around today and Grace is participating in church bazaar at the Presbyterian Church in Cortez. She invites me to a 10 soup luncheon and I meet her at the church. I also get to meet her niece Molly who lives part time in the old restored cabin out on the Greenlee Ranch. Grace has my old rocking chair stored there until I get moved into the house in Rico. Great lunch and I take a homemade apple pie and tamales home with me.

I've gone to Slavens Hardware again for some electrical wire and a chimney pipe hole cover for the 3rd floor. Hopefully Mike Hagen will be on the job today and complete the chimney above the roof in the next couple of days.

Next stop is the barber shop in Cortez for a really past due haircut. Two old guys who had separate shops in Cortez have now combined forces in one location to keep expenses down. I haven't been in a barber shop like this in years...they tell me they are a disappearing breed these days...

Big R is next on my list, a large ranch supply store. I've decided to splurge and buy myself a new Carhartt work jacket. I find what I need along with a new hole saw and head next door to Wal-Mart to return my cheap Carhartt knock off. I've only had it a month and the zipper has had it. I sure don't like cheaply made things and would not recommend buying one, even if it is 1/3 of the price! I've picked up a few groceries for myself and Mary Jane. Max ,our Maltese Terrier, is my patient traveling buddy today and he gets a walk at nearly every stop.

Back in Dolores, I stop at the local food market for some produce which I like better than the big stores in Cortez. Also, Wal-Mart still doesn't carry spinach which Mary Jane has requested and luckily they have it. I stop again to pay Val for the lumber and head back downtown to one of the old antique shops located in the old Exxon Mercantile Store.

I've found an old kitchen cupboard that I really like; one of the doors is missing but the owner of the store points out that the door is hidden in the compartment below. When I ask for the price she shows me the hidden tag and it turns out the cabinet was made in Dunton, Colorado, a tiny town up the west fork of the Dolores River. My grandfather used to snowshoe over the mountain in the winter time to the dances held in Dunton. Dunton is now all restored and privately owned. It boasts its own hot springs pool, a place my mother used to swim in her younger days. The store owner sends me across the street to see if I can talk to the woman who actually owns the cabinet and we strike a deal. I will stop by on my way to the Durango Airport to pick up Lynn in a few weeks and pick up the cabinet. The owner is happy too that the cabinet will stay in the local area. My grandfather loved Dunton and several pictures I have inherited will go nicely with the cabinet.

I stop now at my Aunt Dotties and have a quick visit with her which I always enjoy. She will be headed back to Texas soon to visit family and hates to leave. I am amazed how much milder the weather is down canyon. It's only 38 miles but what a difference when you drop in altitude 2,000 feet.

On the way home I stop at Mary Jane's tiny old sheep trailer. While she has a telephone she has no electricity, running water or heating system. Her place is clean, neat as a pin and nice and warm with her small 2 burner wood cook stove. It's dark when I arrive and she has only her kerosene lamp to light the place. We talk for several hours about the photos which she has really enjoyed. She has completely reorganized them for me in the folder I have them stored in. She has had several visitors that day including Richard Lincoln, a longtime neighbor, whose father Charles Lincoln was one of my grandfathers good friends. I've not met the man, but he owns the small house on main street just south of the Rico Hotel. I hope I will get to meet him soon.

Richard was kind enough to drop off a copy of a letter from Percy Krantz, an old surveyor from Rico who was also another friend of my grandfathers. I have several photos of him in front of the old Rio Grande Southern Depot. I've really enjoyed Mary Jane's company and love to hear about her experiences over the last 83 years in the valley here. She spent most of her life on horseback with cattle herds and knows this country like the back of her hand. I admire her simple life and respect for the land here and her connection to it. She's led a most interesting life. She has enjoyed the oak kindling from our last trip and I will bring another load down to her when I return.

It's evening when Max and I return, it's been a long day...

I've stopped at Val Truelsen's place in Dolores. He was referred to me by Corky McClain, the plumber who had come to Rico last week to look at doing my heating system. Corky was a good friend of my grandparents, Chuck and Lenore Lee. Corky reminds me of an incident that happened 30 years involving my grandmother. For years they had lived next door to old ramshackle run down house that had been a rental with some fairly seedy tenants. The house had come up for sale and my grandparents had bought it hoping to keep more bad tenants out of the house. My grandmother needed a new garbage disposal one day and offered Corky a deal of a lifetime. She actually traded the entire old house for a garbage disposal for their own house. Corky, thinking it would be an easy house to move, did just that by doing some horse trading with a house mover and a foundation man. He installed heating systems for them and these guys moved the house (which had been originally constructed out of Rio Grande Southern railroad ties). The house still stands today near the school in Dolores.

Back to Val's place...knowing many of my related family members, he has given me permission to go into his yard while no one is there. I've come to search for the long rough cut 1 x12's I need to complete some of the siding on the front of the house and also the fascia on the master suite as well as the fascia on the cabin.

Lumber is scattered over several acres and I find only small amounts of the lumber I need in many different areas. When I'm finished I've managed to find 400' of 1 x 12's which will help me complete the job. I've stopped off in town to let him know how much I picked up and will stop later on my way back to pay him. He gives me a reasonable price and with a full load of lumber poking out of the back of my truck, I head for Cortez.

First stop is the drive up window at the bank for some quick cash and a pee break for Max.

Next, I stop at Belt Salvage to see if I can find some rusty steel grate for my steps, but nothing in the scrap pile. Still I find a great piece of 1/4" sheet steel that's come out of laser cutting shop. It has perfectly cut little boomerang shaped pieces cut out of a blank. I love the shape and it will make a nice table or grate for something in the house. I also find a large rock screen for sifting different sizes of gravel. I love the way this stuff looks; it's like a large scale woven cloth with wire 1/2" thick. Needless to say, I don't leave empty handed.

Next door to Belt is Standard Plumbing and I've stopped in to pick up some PEX fittings for my water system. It's about closing time and I decide to call my cousin Grace to see if she and Pete would like to have lunch. Pete is not around today and Grace is participating in church bazaar at the Presbyterian Church in Cortez. She invites me to a 10 soup luncheon and I meet her at the church. I also get to meet her niece Molly who lives part time in the old restored cabin out on the Greenlee Ranch. Grace has my old rocking chair stored there until I get moved into the house in Rico. Great lunch and I take a homemade apple pie and tamales home with me.

I've gone to Slavens Hardware again for some electrical wire and a chimney pipe hole cover for the 3rd floor. Hopefully Mike Hagen will be on the job today and complete the chimney above the roof in the next couple of days.

Next stop is the barber shop in Cortez for a really past due haircut. Two old guys who had separate shops in Cortez have now combined forces in one location to keep expenses down. I haven't been in a barber shop like this in years...they tell me they are a disappearing breed these days...

Big R is next on my list, a large ranch supply store. I've decided to splurge and buy myself a new Carhartt work jacket. I find what I need along with a new hole saw and head next door to Wal-Mart to return my cheap Carhartt knock off. I've only had it a month and the zipper has had it. I sure don't like cheaply made things and would not recommend buying one, even if it is 1/3 of the price! I've picked up a few groceries for myself and Mary Jane. Max ,our Maltese Terrier, is my patient traveling buddy today and he gets a walk at nearly every stop.

Back in Dolores, I stop at the local food market for some produce which I like better than the big stores in Cortez. Also, Wal-Mart still doesn't carry spinach which Mary Jane has requested and luckily they have it. I stop again to pay Val for the lumber and head back downtown to one of the old antique shops located in the old Exxon Mercantile Store.

I've found an old kitchen cupboard that I really like; one of the doors is missing but the owner of the store points out that the door is hidden in the compartment below. When I ask for the price she shows me the hidden tag and it turns out the cabinet was made in Dunton, Colorado, a tiny town up the west fork of the Dolores River. My grandfather used to snowshoe over the mountain in the winter time to the dances held in Dunton. Dunton is now all restored and privately owned. It boasts its own hot springs pool, a place my mother used to swim in her younger days. The store owner sends me across the street to see if I can talk to the woman who actually owns the cabinet and we strike a deal. I will stop by on my way to the Durango Airport to pick up Lynn in a few weeks and pick up the cabinet. The owner is happy too that the cabinet will stay in the local area. My grandfather loved Dunton and several pictures I have inherited will go nicely with the cabinet.

I stop now at my Aunt Dotties and have a quick visit with her which I always enjoy. She will be headed back to Texas soon to visit family and hates to leave. I am amazed how much milder the weather is down canyon. It's only 38 miles but what a difference when you drop in altitude 2,000 feet.

On the way home I stop at Mary Jane's tiny old sheep trailer. While she has a telephone she has no electricity, running water or heating system. Her place is clean, neat as a pin and nice and warm with her small 2 burner wood cook stove. It's dark when I arrive and she has only her kerosene lamp to light the place. We talk for several hours about the photos which she has really enjoyed. She has completely reorganized them for me in the folder I have them stored in. She has had several visitors that day including Richard Lincoln, a longtime neighbor, whose father Charles Lincoln was one of my grandfathers good friends. I've not met the man, but he owns the small house on main street just south of the Rico Hotel. I hope I will get to meet him soon.

Richard was kind enough to drop off a copy of a letter from Percy Krantz, an old surveyor from Rico who was also another friend of my grandfathers. I have several photos of him in front of the old Rio Grande Southern Depot. I've really enjoyed Mary Jane's company and love to hear about her experiences over the last 83 years in the valley here. She spent most of her life on horseback with cattle herds and knows this country like the back of her hand. I admire her simple life and respect for the land here and her connection to it. She's led a most interesting life. She has enjoyed the oak kindling from our last trip and I will bring another load down to her when I return.

It's evening when Max and I return, it's been a long day...

Nov 3rd - Rafters Up

Bill left yesterday for a trip to the Grand Canyon and will return on Monday. R.D. and Pat install the skylight in the morning, so Pat can run the bituthane around the skylight as well as the flashing for the metal roof.

R. D. and I move downstairs and tackle the two windows in the north cabin living room. It doesn't take us long and the windows are in. R.D. takes off early to head out for a golf weekend.

I have had the job of unstacking and restacking a load of reclaimed shiplap so I can get to the heart pine decking lower in the stack. We will use this for decking on the rafters of the master suite. The final part of the day I set up the sawhorses and a straight rip guide to straight line the heart pine and ready it for roof. I have also covered up as much lumber as possible as there is small chance of rain tomorrow. Hopefully it won't rain or snow much, but looks like a major snow storm coming in Thursday. We have to get the roof on.

Gary and Pat are progressing on the roof, but it's not going at the rate I would like to see. Hopefully Monday we can really crank on it and get it completed. Greenbay has been cutting barge rafters and lookouts from the pile of white oak rafters I've selected. He comments that many of the rafters are really furniture grade quarter sawn oak and he can count the total knots on all the roof rafters on less than 2 hands. It's nice stuff, almost too nice to use for rafters, but they are on the roof, nearly ready for decking.

Thursday, November 02, 2006

Nov 2nd - Roof Begins

This is our 7th day in a row for sunshine; something I have come to really appreciate and be thankful for. What a relief to not have to deal with the weather during this time of trying to get things dried in.

R. D. has continued on the windows with Bill and they have sealed up the edges of windows nicely with bituthane strips. These will keep the moisture out. The final large windows in the 2nd floor sunroom are now installed and the whole place is really beginning to look like a real house.

Gary Gass and Pat have begun the roof and have a good part of the flashing on the main structure of the roof as well as the sheets of metal on the shorter front section of roof over the west bedroom. Gary has brought his harnesses with him which make it easier to work, knowing if you should slip, the harness will prevent you from having a nasty fall. Thank God these guys are comfortable and good on the roof.

Greenbay has built the posts for holding up the long ridge beam which has a 20' span. Later in the day 4 of us lug the 4 x10 up onto the master suite floor and walk each end up ladders and drop it into the beam pockets Greenbay has constructed. He has to add a short section on each end of the beam for overhang to match the other exposed beams on the house. Using metal straps everything is fastened and falls into place.

My job today has been straightlining the white oak 2 x 6s and making them a consistent size and easier to install over the master suite. These white oak boards that I pulled out of a barn in Iowa were probably installed green and so what once was a straight edge is now wavy, curved or hooked. Cutting one edge straight will give a nice surface for attaching the decking above. I have also cut down enough blocking to install between the rafters at both the peak and the exterior walls.

Some great progress was made today. I pray for more good weather.

Nov 1st - Roof Steel Arrives

I had the great fortune this morning of instant messaging my good friend, Surin, in Thailand. If you haven't checked out the Western Forest Conservation Club's (WFCC), please click on the link on this blog. This small group of Thai men and women does an amazing job in protecting one of the last and largerst great forests remaining in all of southeast Asia. It's called Thungyai and it is part of the great Western Forest Complex. If you have ever considered giving to a charity, these folks are for real and have made a huge difference in Thungyai. I hope you'll check it out and find it interesting reading about what these guys are up to. I have had the simple pleasure of visiting Thungyai on 2 separate occasions....

Surin, if you are reading this, this blog posting is dedicated to you and all WFCC members. I have promised to send you pictures of what the mountains look like here and today I traveled across Lizard Head Pass in the San Juan Mountains of southwestern Colorado. I stopped and took some photos. Lizard Head Pass is over 10,000 feet in elevation and Lizard Head Peak is well over 13,000. I hope you will come in the following year and enjoy a few days of this beautiful place. Enjoy the photos!

As I mentioned, I have gone over the pass to Telluride to pick up the steel I have ordered for the roof. This short stack of steel corrugated roofing weighs over 4,000 lbs and my order has included all the steel, flashings, felt and screws to attach the metal. Up here the popular steel is one that rusts and blends into the surrounding historical district. That's right a roof that rusts. I definitely notice the extra weight on my trailer coming up and over the pass.

Pat and R.D. have continued with window installation in the upper section of the main part of the house. By tomorrow we should have a majority of the windows installed.

Greenbay and Bill have now completed all of the exterior walls of the master suite and these are actually the final exterior walls we will be framing. It has been a major job that is coming to a close soon. At the end of the day Greenbay has cut the peak on the the top ridge beam and tomorrow this will be set in place. Bill has continued with cutting Tyvek house wrap for the few places on the 2nd floor that need completion.

I have recruited Bruce, aka Smiley, for helping me in the cleanup and organization of the place. Within an hour we have the 2nd floor and lumber area out back looking considerably better. Gary Gass, another carpenter here in Rico, shows up to take a look at the roof where he and Pat will start installing the roof panels tomorrow. Hopefully Hagen will be along shortly to complete the fireplace chimney soon.

Oct 31st - More Windows

Pat is up on the roof a good part of the day preparing a work platform for Mike Hagen to finish the chimney and get the stone work completed above the roof. It amazes me how comfortable he is and how much he likes being on the roof.

R. D. is preparing window openings by firring out each opening 1" which is how thick the siding is. We install the bay window into its opening as well as the north kitchen and powder room windows. Once we have a system down, it goes quickly and smoothly. The windows just look fantastic.

Greenbay and Bill have completed the south wall of the master suite and we stand the wall up and nail it in place. The layout and building of the final exterior wall has begun as well.

I've spent the entire morning unloading all the junk and misc lumber that has been sitting on my trailer for over a month since we cleaned up the lumber yard and moved everything from down on the highway. I have to empty the trailer as I need to take it to Telluride tomorrow to pick up the steel for the roof. Much of the material on the trailer is firewood, but lots of misc wood that we will use in the final framing also has to be stacked with similar type wood in the yard. I have also covered up several exposed piles of lumber with new plastic to make some attempt to keep things dry.

Oct 30th - More Progress

This morning I have the job of getting the plumbing run through the bay window roof and into the area that will supply drain lines to the laundry and shower areas on the 2nd floor. My hole saw has just cashed it in and so I revert to using a sawzall to cut holes through the rim joist and into the bottom plates of several walls upstairs. The plumbing must be contained in an area above the bottom edge of the floor joists. Unlike a drywall ceiling and walls, this area is particularly a challenge in hiding pipes because of the exposed open ceilings and beams and solid log walls.

Pat has changed slightly the location of the north kitchen window to provide room for outlets and switches in the kitchen area. R.D. and Pat are now constructing the roof over the bay window area. It will need to match as closely as possible the design of the main roof. They have used rough cut reclaimed 2 x 10's on the framework and scrap 1 x material left over from the main roof.

Bill and Greenbay are busy up on the master suite framing the east wall. This one has taken careful planning as well as has a much lower side wall height due to the overall height restrictions of the entire addition. They have completed the wall and we stand it up and nail it in place. Greenbay's careful planning has made it possible to stand up the whole wall with the OSB attached as well as the Tyvek house wrap.

Bill has spent the early part of the day reframing the door opening on the west wall. It has to be moved approximately a foot to the north because of the rafters in the main part of the house being low in that area of the roof. I've laid out the interior wall intersections of the master walls so Greenbay and Bill can begin framing the north and south walls of the master.

Today is a milestone as I have installed the first window in the northwest corner of the north bedroom. It looks great and makes me anxious to get the balance of the windows in.

Subscribe to:

Posts (Atom)